Our Company

Why La Querce?

Our Name, a Great history

In the beginning the tanning powder destined to the vegetal tanning process, came from Oak trees,”La Querce”, in our local language.

This tree is not only the historical background for our natural tanning process, but is also a symbol of strength and continuity with the past: a past still present in our mind, for the processing of a product that looks to the future..

Our Origins

A tradition started longtime ago

A tradition that started log time ago…

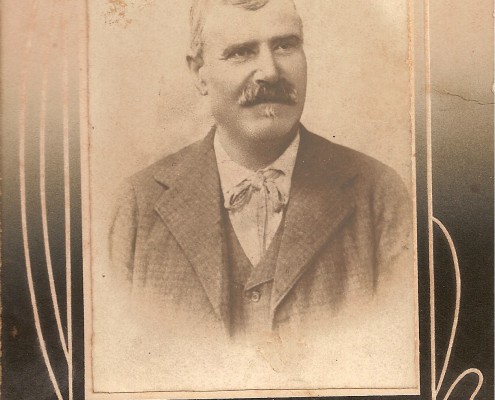

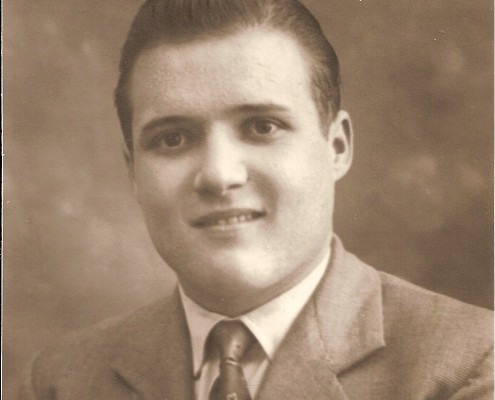

The Cuoificio La Querce comes from the ancient Conceria Dani, founded in late 1800. After a short period of inactivity due to the Second World War, the production was resumed in 1946 under the name of Conceria Dani Guido and Piero.

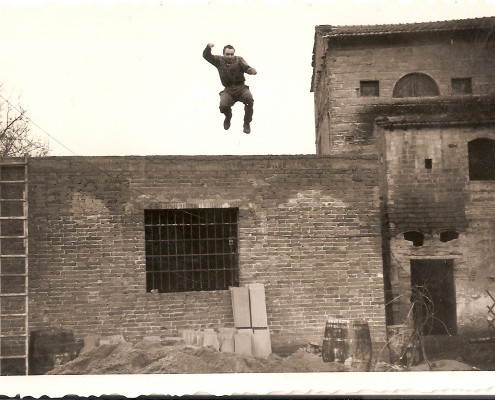

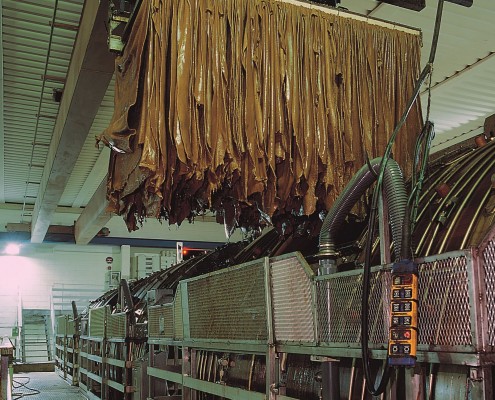

On 1980 some new relatives joined the company, the name was transformed into Cuoificio La Querce and the tannery was moved to a new modern production plant.

The new plant gave Cuoificio La Querce the possibility to meet all the demanding requirements of a modern vegetal tanning process: the full respect of a centuries-old tradition, the quality criteria of a modern production, and the environmental respect of our territory.